In two, the Deep Groove Ball Bearing operation and maintenance Reliable maintenance work is to ensure that the bearing long-cycle operation of the main means of equipment for a period of time should be timely and professional and technical personnel to inspect and maintain the equipment, Mainly in the following areas: 1 Check the bearing operating temperature, below 65 degrees. 2 Check the amount of axial movement of running parts. The main bearing clearance is not meet the requirements. , Corrosion, pits, cracks, etc. 4 lubricating oil or grease lubrication, to be promptly replaced or added, but not too much, requiring one third to one half of the lubricating oil, grease one third Third, the case analysis of urea deep hydrolysis device as fertilizer industry wastewater treatment terminal device, the core equipment hydrolysis pump for multi-level, high Speed, high-temperature, high-pressure equipment. Over the years running unstable, so that the production of urea be greatly affected. Mainly in the deep groove ball bearing short life cycle, machine vibration and other failures .After everyone's analysis that its.

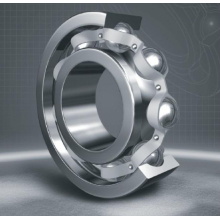

Model: 6023 Single Row Deep Groove Ball Bearing

Brand: AUTO

Series: deep groove ball bearings, single row, no seals

Shape size

d: 32

D: 60

B: 23

Luoyang Auto Bearing Co., Ltd. is located in the industrial park of Luoyang,which is one of the four great ancient capitals of China.Our company is the member of China Bearing Industry Association,cooperating with State Quality Supervision and Testing Center for bearing.Our company is a professional bearing manufacturer which integrated with research ,development and marketing services.

Our major products include deep groove ball bearing, Spherical Roller Bearing, slewing ring, crossed Roller Bearing and other all kinds of high precision bearings.Our products are widely applied to motor industry,mining metallurgy,wind power generation,petroleum drilling,automobile and motorcycle etc..

Our company not only possesses advanced bearing manufacturing equipments and international first-class measuring instruments, but also has strong strength of manufacturing, inspecting and testing the high precision and reliability bearings.Each process is in strict accordance with the ISO9001 quality management system,which effectively guarantees the precise of products and stability of the performance. AUTO bearings are mainly exported to the United states,South Korea,Europe,etc., which have reached the high level of foreign similar products.

The soul of our business culture is [Detail makes competitive, innovation makes first-class".We believe the production and management philosophy of [quality wins ,casting competitive products".The company adheres to the zero-defect quality management for meeting customer requirements.

Product Categories : Deep Groove Ball Bearing > Single Row Deep Groove Ball Bearing

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now